In describing how it is possible to build a safe, reliable airplane for very little money I mentioned covering the wings with polyester fabric shrunk tight with a clothes iron and sealed with urethane varnish into which you've mixed some powdered aluminum. (The original message, posted a couple of years ago, was titled ‘Flying on the Cheap.' It has since been reposted widely and has generated a lot of email.)

Boy, did I catch hell :-)

Alas, the majority of the mail was negative, some politely so, the general tenor being that all good airplanes were always made entirely of materials certified for use in aviation. Then there were those a bit less polite, telling me I was stupid, foolish or running some kind of scam.

Well... okay, however worthless that opinion might be. And it is worthless, since it means the Wright brothers would never have flown, nor would the Pietenpol, Jeanie's Teenie, Sonerai and virtually everything designed by Burt Rutan except the Vari-Viggen. But thank you for taking the time to offer your opinion. You can be sure it will get all the attention it deserves :-)

For all you other yahoos with a yen to fly, the original message is valid. Indeed, in telling you how you can fly on the cheap I did little more than read a page from the history of American aviation, describing wooden wings and fuselages of welded steel tubing. But time marches on and some of the things I said, such as using fabric from your local fabric store and picking up a packet of powdered aluminum from your local paint store, are no longer correct, at least in detail.

The truth is, powdered aluminum is still available. But not from your local paint store, as it was here in Vista, California (and I assume everywhere else) at least until 1975 or thereabouts, when I last bought some. Nowadays powdered aluminum is considered a pyrotechnic, probably because it is one of the components in thermite. All that means is that you must register with a supplier of pyrotechnic chemicals and buy the stuff from him. The internet can provide you with the addresses of several who sell to the public... once you fill out their forms.

Or you can buy powdered aluminum paste from someone like Wag-Aero or Aircraft Spruce.

In a similar vein some of you have discovered that heat-shrinkable polyester fabric is no longer available from most local yardage stores. I didn't know that and apologize for sending you on a snipe hunt. Let's see what we can do about it.

Using the internet I tracked down four varieties of 100% Polyester fabric and bought sample quantities of each. Then I tested them.

But the first step was to establish a standard.

Out in the shop there's some boxes of scrap fabric, remnants of Covering Jobs Past. The certified stuff is in one box, generic stuff in another. Along with rat turds and lotsa other crud the box of uncertified, generic 100% Polyester fabric scraps yielded up a piece about two feet wide by 66" long. Filthy of course, but you can wash it, which is what I did. Cold water. Not a lot of soap. Two rinse cycles. Air dry.

After being washed the dacron fabric came out wrinkled like a piece of aluminum foil that had been wadded up then flattened out. Looks like hell but looks can be deceiving. I made up some test frames, gave them a seal coat of varnish and glued the Standard fabric to a frame.

As soon as that stuff even saw the iron, the wrinkles vanished. A little more heat and it shrunk up so tight it threatened to warp the frame. Given a coat of Home Depot dope, it got even tighter and when cured, sounded like an Inuit drum. Bottom line: This is good stuff for covering a simple airplane. (The fabric is probably from Aircraft Spruce, catalog number 09-00300. Three ounces per square yard [or thereabouts], 66" wide and probably about four bucks per linear yard at today's prices.)

So there was my Standard, against which I could compare my Internet Fabric Store Wing Covering Fabric.

The first test was to cut a 2x10 inch strip of fabric and iron it, first on the ‘low' setting, then on ‘high.' Only one of the samples shrunk and then only by 2% or so. The next step was to attach the samples to frames to see if I could produce a drum-taut surface. The results were... marginal. The fabric that did heat-shrink came out pretty good but the others took a couple of coats of nitrate dope to tighten up and didn't have that resonant drum-like BONK! when tapped. (If it don't BONK!, don't fly.)

One of the fabrics I tested was unbleached 100% cotton muslin. I included it in the tests because a couple of you don't live in Detroit. Or even in the USA.

After being tacked to a frame (the other samples were attached with contact cement) the cotton tightened up beautifully with water and gave me a good drum sound after two coats of dope. But it wasn't as smooth as Grade A cotton, weighed about 6.5 ounces per square yard going in and one hell of a lot more after it soaked up two coats of dope. That wouldn't be so bad if we were talking Pietenpol's and Model A Fords swinging an eighty-inch prop. But we're talking single-place, VW-power and a twenty-four foot wing span. And cheap. The biggest part of the secret to flying on the cheap is to keep things light.

In some parts of the world unbleached cotton muslin may be your only option. It'll work but it's going to run about four times heavier than dacron, so plan accordingly.

The polyester fabric that did shrink and did play the drums was ‘Poly Suit Lining' material from fabric.com. Ninety-five cents a yard. Width is about 45" and the weight something under two ounces per square yard. No, you can't buy none because you apparently already have, you rascals! After the tests, which I've been sharing with the guys who are actually building the Practice Wing, I tried to order some more... and was told they were sold out.

So what's the bottom line? I think you should buy the good stuff; save yourself some headaches. (A suggestion I've voiced before.) But yeah, if you know what you're doing and if you want to invest some time in testing fabrics that are locally available, you can probably find something suitable for covering a light airplane. The Dream stays alive but the path is a bit steeper.

- - - - - - - - - - -

After receiving the fabric via UPS, cutting the first test-strips and discovering they did not shrink, I devoted some time to trying to find out why, since I'd been able to buy heat-shrinkable polyester from local stores in the past. (I've already mentioned part of this in an earlier post; what you see here has to do with the fabric I got via the Internet.)

Now this was kinda funny so bear with me.

After a bit of effort (quite a bit, in one case) I managed to reach humans at the places from which I'd ordered fabric. But any mention of having the stuff shrink produced Instant Denials. Not our fabric! No way, Jose! All of our polyester fabrics are pre-shrunk!

It took a while to get across to them that I wasn't angry, didn't want my money back and wasn't accusing them of anything. At least, for two of them. One lady remained convinced I was trying to lodge a complaint and insisted I do so in writing. Ah well... But with the other two, the penny finally dropped and here's what I was told. Heat-shrinkable polyester fabric was fairly common at one time... but no one has made anything like that for at least ten years.

(Now here's the funny part :-)

...but if I did receive some non-preshrunk fabric, and if it was one of their Clearance Sale Items (which the Suit Lining Material happened to be) then I had no recourse because somewhere in the fine print on their web site was some legalese boilerplate bullshit stating that all such sales were final.

So, no, heat-shrinkable polyester fabric is not commonly available. And if it was, they'd never admit it :-)

- - - - - - - - - -

So... whatcha gonna do? One option is to do what I did: Buy samples and test them. And there's a bit of a tale here, too, because heat-shrinking isn't the only way to tighten fabric. As I mentioned above, the sample of unbleached (and I assume un-Mercerized) cotton that I tested shrinks like a cheap wool suit, very similar to the way Grade A Cotton aircraft fabric shrinks. Just sponge on warm water and let the stuff dry. My particular sample of unbleached muslin had quite a bit of sizing and would not accept a light sponging of water. But after adding one drop of liquid detergent to a gallon of warm water (i.e., as a wetting agent) and scrubbing it onto the framed fabric with a sponge, it soaked it right up. And as it dried, it shrank.

- - - - - - - - - - -

If you are very careful to apply your fabric with no wrinkles at all, you can get a usable surface by shrinking it with dope or some form of sizing. The Colditz Glider was covered with cotton bed-ticking, carefully sewn and tacked to the airframe. It was then made taut by coating it with a starchy sizing the prisoners produced from some kind of cereal; oatmeal or millet or something like that. This is similar to what happens with common wall-paper paste (which is basically wheat flour). Boiled to release its gluten and applied wet, the stuff shrinks as it dries.

I don't expect anyone to paint their airplane with library paste. What I want to get across here is the process of applying some form of coating or sizing that shrinks as it dries. And the best example of that is aircraft dope.

But here again, the success of this procedure will depend largely on your experience. And if you haven't used dope you should do some experiments to teach yourself how. Which leads to the next part of this story :-)

- - - - - - - - - - -

After sticking the fabric to the frames and seeing the stuff remain as limp as Odie's tongue I grabbed a can of dope and... I grabbed the next can of dope and...

I didn't have any dope. I had several cans that used to contain dope. Now they contained a cellulose potato chip.

Dope is cellulose nitrate lacquer. It isn't very expensive and it's fairly common although if you want it to say ‘Aircraft Dope!' on the can you'll probably have to order it from an aircraft supplier and pay a premium to boot. I used to buy it at the same paint store where I used to buy powdered aluminum :-) The paint store is no longer in business, thanks to Home Depot so that's where I went. Sure enough, tucked away on a shelf in the paint department were several gallon cans labeled ‘CLEAR CELLULOSE NITRATE LACQUER.' I bought a can. (So who uses dope besides airplane builders? Luthiers, for one. Sandy Eggo county, especially up here in the northern part, is over-run with luthiers. You rarely see them but on nights when the moon is full you can hear them, playing out there in the hills.)

The stuff from Home Depot looks and smells like real dope but doesn't tighten up as much, although more so than ‘non-tautening' aircraft dope. It worked well enough for the tests. If I couldn't get anything better I'd be willing to fly with it. But I don't think you should; not unless you've got a lot of experience with fabric & dope (in which case you probably wouldn't be reading this :-) The experience-factor is fairly critical here because the first coat of dope is the one that does most of the tautening and you need to apply it properly, which means encapsulating the fibers when you're working with polyester and that calls a fairly thick viscosity. But with cotton (or other absorbent fiber) you want to saturating fabric, which calls for a fairly thin viscosity. The tricky bit here is the ‘fairly thick' vs ‘fairly thin' because there really isn't that much difference between them. To adjust the viscosity you pour some dope into a can and leave it set to thicken (i.e., increase the viscosity) or add thinner to reduce the viscosity. Temperature is also a factor as is the orientation of the work. Some experiments will show you which direction you need to go... but only for that particular set of prevailing conditions. Fortunately, when covering just one airplane, the tail feathers usually provide enough experience to let you do a good job on the wings.

- - - - - - - - - - - - - - -

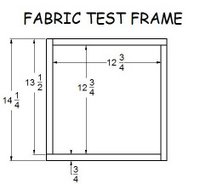

I've mentioned test frames a couple of times and can see the question marks slowly rising over several heads, so...

Home Depot sells what they call "1x2 Whitewood." That's Yuppie-speak for Western Hemlock furring strips, 3/4" thick, inch and a half wide by eight feet long. Price varies according season, store and availability. I've bought them for as little as thirty-nine cents and as much as $1.49. I tend to keep eight or ten lengths on-hand. Like most of Home Depot's wood it's mostly crap but now that they driven all the real lumber yards out of business, for lots of folks they're the only source of lumber.

So go buy yourself some of that 1x2 whitewood crap. We're going to make some fabric frames.

A fabric frame is just an open box over which we stretch a piece of aircraft fabric in order to teach the newbies how to tack, glue, stitch and dope. Back in the Good Ol' Days, whenever that was, we'd use an old drawer or a lug-box. The size isn't especially important but for polyester the frame should large enough to accept a standard clothes iron, which is what we use to shrink polyester fabric.

Never built a fabric frame? See the drawings - FABRIC01 thru FABRIC03 (These are in the ‘Files' section of the Chugger Group, under WINGS.)

Keep in mind that our goal here is to work with fabric rather than the frame. Don't go overboard on the thing. Chop the furring strip into lengths, start a 4d nail on each end, smear on a dob of Gorilla Glue and nail that puppy together. Then hang it up and do another. Make three or four of them.

Then leave them alone for at least 24 hours.

- - - - - - - - - -

Looks like hell, don't they? :-)

Don't worry about it. In fact, there is an extremely valuable lesson in those awful looking fabric frames. Follow me through here and see if you can pick it up.

Got your angle-head grinder? Install a flat flapper-type sanding disk. Coarse is good. Fire it up and get rid of all the glue squeeze-out. Keep the sander flat; don't gouge the wood.

See how those corners are mis-aligned? Make them line up. Go on; use the flapper wheel to even out the high side, taper it back a couple of inches. Yeah, it's a mess. Don't worry about it. (You gotta trust me here.) Chamfer all the edges. Just knock them down, mebbe a sixteenth of an inch. Use nice, even motions with the angle-head grinder, almost no pressure at all; let the flapper wheel do the work. If you spend more than a minute per frame, you're missing the point.

Got them all cleaned up? Then take your powered sanding block, clip on a sheet of #80 grit and get rid of the sanding marks from the flapper wheel. Smooth things up.

Get a rag, dip it in some mineral spirits and wipe down the frames. This will pick up most of the sanding dust.

Open up a can of VARNISH. Spar varnish is good but so is urethane. If you're an aircraft type you know that nitrate dope will also serve to seal the wood, which is what we're doing. But I'd rather you use varnish.

Lay on a full, wet coat of varnish then hang the frames up and use the brush to smooth out any drips. If you don't have someplace to hang them, figure that out before you make them.

Now go do something else. Allow the varnished frames to cure for at least 24 hours.

- - - - - - - - - - -

The varnished frames will come out rough as a cob. If we wanted a dense, shiny finish we'd go after that rough surface with some #120 grit, knock it down and lay on a second coat.

But in this particular case the one thing we don't want is a dense, shiny finish. We want that rough-but-sealed finish because we're going to lay down a layer of contact cement. And contact cement works best when the surface has some tooth. Which is also true in the case of real airplanes and real fabric cement. That was #1 in the Valuable Lesson Dept. Lesson #2 is the fact that you can do the same thing with an airplane.

We always try to do the best we can but being human and building just one airplane, sometimes things don't come out perfect.

Valuable Lesson #2 is the fact that most of the time, things don't have to be perfect to work perfectly well and this is especially true when doing fabric work.

Does the fabric lay smooth? Try it out and see. Just stretch a piece of fabric over the frame and look for irregularities. Sharp corners that have escaped your notice for months are suddenly evident. So smooth them off. Ditto for unexpected low spots, except you fill them; just glue on a filler and sand it flush. Awkward angles that threaten to leave a puckered corner? Glue in a block of balsa and convert the empty corner to a smoothly faired surface.

So long as such irregularities are neither frequent, abrupt nor large, they will have no effect on how well your airplane performs. Resolving minor problems of this sort is one of the realities of fabric work

- - - - - - - - - - - -

I used contact cement to attach the fabric to the frames. Regular fabric cement (FabTac, et al) will work at least as well and costs about the same. I used two coats of cement on the wood, allowing the first to dry before applying the second. The fabric was applied while the second coat was still wet. A third coat was applied over the fabric and squeegee'd through the weave with my thumb. The goal is to encapsulate the fibers of the fabric with the cement. Nothing bonds very well to polyester so we force the cement through the fabric and allow it to bond to itself. There are a host of variations on this theme; for a wing I would use a different method. Experiment; find a method that best suits your situation.

Shrinking was done with a clothes iron reserved for that purpose and already described in earlier posts. I did all the shrinking on the ‘high' setting... then realized you wouldn't have any idea whathell I was talking about. Dug out a thermometer that read to 400 degrees and measured the iron. The second mark on my masking-tape dial produced a consistent 350 degrees Fahrenheit.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

In closing, allow me to offer a word of explanation about ‘Flying on the Cheap' and other messages some folks have found so disturbing.

My dad was an aircraft mechanic. I used to help him. The first time I can recall helping him, I was about seven years old. I stood on a lug crate to push needles back at him through the wing of an airplane. Such chores were kinda interesting for the first five minutes after which I'd hear the Call of the Wild and he'd usually let me go. But most times it was kind of neat to just hang out with my dad, and between the two of us, me poking and him pulling-through and tying-off, we'd do a whole wing.

Other times it was driving rivets. Or helping him sand. Or helping him paint; masking off the NC numbers on the left while he did the right. Pulling wire. Making up fittings. Polishing plexiglas... scrubbing the grime off the belly of the Cub... It never seemed like work.

My dad never ‘taught' me to work on airplanes, as in Major Instruction, with quotation marks and so on. He'd ask me to ‘give him a hand.' Nothing complex; nothing I couldn't understand. Always demonstrated rather than being told or ‘taught.' Always one small step at a time; ‘Do it Right, we won't have to do it Over,' a shared joke always spoken with a smile because that was one of my grandfather's favorite expressions. Waxing the thread, spinning two thin threads across my thigh to make a thick thread, cleaning the oil off the needles before and replacing it after, laying on dope or glue or cleaning brushes or... No ‘teaching' at all. About twenty years of it off and on, from the time I was a child until his death when I was in my mid-thirties.

You'll probably find this funny but somewhere in the back of my adult mind was the notion that everyone who flew planes or worked on them or wanted to actually build one, knew all that stuff that I'd learned without ever being taught. Like the fact it's a Seine Knot (except we called it a Net Knot), tied flat instead of with your toes holding the mesh, your netting bobbin flashing in and out, fast as you could, as automatic as a woman knitting while rocking the baby and carrying on a conversation at the same time. When (and where) I grew up, every boy knew how to make nets. Not just for catching minnows but for basketball hoops and summer-time hammocks and string-bags for your mom and all sorts of other things. Common Knowledge; the stuff that never needs to be mentioned because it's something everyone knows. Like dope and fabric and welding and woodwork and engines and...

Turns out, everyone don't. Which is probably why I see a simple, reliable airplane as something everyone can build, and inexpensively, too... where others see it as a Type Certificated, Approved Aviation-Quality Bureaucratic Impossibility. And they're right. Absolutely. Because if they're positive they can't build an airplane, they won't even try.

-R.S.Hoover

No comments:

Post a Comment