I shouldn't be writing this. I shouldn't have to be writing this, since it covers a topic everyone already knows. Or should. But here goes.

Like most of my articles, this one began with a message from a youngster, the proud new owner of a old beetle. He'd found the 'sermon' files and sent me a message that, aside from the question it contained, told me he hadn't read any of the available manuals. I answered his question and, being the sweet sonofabitch I am, I pointed him toward the books and told him to get hot -- I didn't have time to answer questions he could answer for himself.

Usually, that's all it takes to stub the tender ego of youth -- I didn't expect to hear from him again. But I did.

Okay, he sez, he's got the manuals. And he's impressed. He has the Bentley, the Muir and the Haynes and he's reading as fast as he can and if I had the time, would I please tell him how much grease he should put in his fittings when he gives his '64 bug a lube job. It squeaks, he sez.

Instead of telling him, I pull out the manual, to point him toward the proper page and paragraph. But it wasn't there. Haynes says only to grease the thing -- no mention of how much. Muir sez the same thing, except they screw things up by passing out bum dope on what to do about a bad Zerk fitting(*). The Bentley manual does a little better, saying "Continue with the greasing until fresh grease begins to emerge from the lubrication points." (Page 8-8 in the Bentley book for bugs.) So I tell him where to find it and get back to doing what I was doing, which has to do with propane and computers and all kinds of neat stuff.

Back comes another message, quick like a bunny. It's a Yeahbit message: "Yeah, I read that... but that takes something like twenty strokes and all of my friends say that's 'way too much."

Ah yes -- peer pressure, and the deadly need to look kewl. This fellow's friends, one or two of whom might own a Volkswagen, were giving him the benefit of Conventional Wisdom. And then there's the Muir manual, which sez to stop greasing as soon as you see grease come out. Wrong.

I sent the kid a long, carefully worded message explaining that the purpose of a lube job is to replace the chassis lube, offering him some tips on how to keep things greasy so they'll last a long time. The kid fires right back to say that after sending his second message he's checked with his dad and the local quickie-lube emporium (shudder) and everybody agrees... one or two squirts of grease is all you need. He also had some rather sharp things to say about lube needles. (see below) Faced with the possibility of looking un-kewl, the kid had taken the easy way out.

Good-bye, kid. Good luck in the contest.

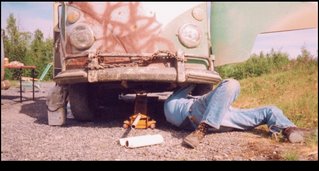

I go back to playing with vaproizers and trying to figure out how to fit a one hundred sixty liter propane tank in a bus and I'm laying out there under Grendel, looking at a patch of blue sky through her 'good condition' cargo bay when I begin to wonder.... doesn't everybody know the whole idea is to change the lube rather than just add a bit?

Lube Change vs Oil Change

A lube job is in fact the replacement of the lubricating grease, not just its replenishment.

Lubricants -- oils, greases and soaps -- literally wear out. Their long-chain molecules are sheared by heat and pressure and over time they become contaminated with moisture, dust -- and in the case of engine oil, with combustion products. We deal with worn-out, contaminated lubricants by replacing them.

Everyone knows they have to change their oil rather then just topping-up. And most of us know we have to change our tranny-lube every couple of years. And we scrub all the old grease out of our wheel bearings and the spindle bore and repack them with new grease...

So what's different when it comes to chassis lube? A lube-job is just another form of oil-change.

When doing a lube-job, too make sure you do a proper job of it, you keep pumping until you see the new grease coming from the part. Yeah, it's a mess -- the old grease gets all over everything. You put down some newspaper or something else disposable to catch the globs of falling grease, and use paper toweling to wipe any any grease that clings to the part. When you're done, you should put a cap of some kind over the Zerk fitting. Cars used to come with neat little rubber caps for this job, and replacements were commonly available, although I haven't seen their like in recent years. Instead, I've taken to molding aluminum foil over the Zerks after every lube-job.

Lube jobs, like oil changes, are not carved in stone -- you can't just go by miles traveled or a set period of service, you need to pay attention to the type of miles traveled and the conditions encountered during a given period of service. Normally, your steering and front suspension needs its lube replaced about every six thousand miles -- that's the spec. Then comes the fine print. Rough roads? (meaning lots of action from the suspension) -- replace the lube more often. Dusty roads? (meaning more contaminants, plus the wicking-effect of dust) -- replace your lube more often. (Oddly enough, a vehicle that does not drive very much needs its lube replaced more often than one which does.) It's all there in the manuals (at least, in most of them :-). And has been, for about seventy years.

Keep it greasy, it lasts longer.

It is not just proper lubrication that prolongs the life of the vehicle, there is also the implied cleaning that accompanies any lube-job. Dirty, dusty or harsh conditions, you need to clean your undercarriage more often. That's what you do before you change the lubricant, just as you clean off your engine when do an oil change.

Long, Boring (but real) Example

A fair example of the frequency at which you may need to change your lube was the run to Inuvik last year. Round trip, it was only eight thousand miles but there were so many miles of dusty, unpaved road I thought it best to double-up on my lube jobs, doing the greasy chore three times during the trip.

I've even got the photos to prove it :-)

Following the trip to Inuvik I ran down to Cabo as a preliminary for our up-coming 12 July trip. I had the bad luck to run into the tail-end of a hurricane and had to ford a number of flooded vados. Soak your bus in water, you gotta change the engine oil, tranny lube and chassis grease. All tolled, the bus enjoyed five lube jobs for only fifteen thousand miles of service. (There was a three-thousand mile run to Kansas City in there somewhere.)

Doing the Deadly Deed

There are many different types of grease. For most chassis lubrication needs any good grease will work but see your manual for their recommended specifications. For CV's you want a different formualtion than the grease you use for your torsion bars-- one more suitable for high pressures. But CV lube is great stuff for tie-rod ends and ball joints.

There are three basic types of manually-operated grease guns but all of them are in fact a form of hydraulic pump, designed to pump grease rather than oil. The lever-type gun can usually generate about 3000 psi, more than enough to force the thick grease into the finest fitting.

It is common practice to maintain a different grease gun for each type of grease your vehicle requires. I use a moly-based grease for CV's, tie-rods and ball-joints, a lithimum-based grease for the torsion-bar and steering knuckles.

Grease is sold in convenient cartridges, although you can bulk-load your gun if you wish. Wheel-bearing grease is normally sold in cans. The best wheel-bearing grease has very long molecules -- it's called 'long-fiber' grease -- and is unsuitable for use in manual grease-guns. Each cartridge holds about 400 grams of grease -- about fourteen ounces. It takes about eight ounces of grease to do a proper job on an old bus. Later model buses have fewer fittings -- more 'Lifetime-lubricated' parts waiting to fail -- and so takes less grease per job. On the Inuvik run I used two tubes of grease and had to replace one Zerk, apparently kissed by a rock.

Zerks! Zounds! and Needles

A Zerk fitting is a nipple shaped to match the nozzle of a grease-gun. The grease passage through the nipple is closed with a check-valve, a tiny steel ball supported by an equally tiny spring. Left exposed, Zerk fittings go bad quite quickly which is why they should always be protected with a cap.

Being a lubricated joint, tie-rod ends were once fitted with Zerk fittings and many still are. The same is true of ball-joints. Unfortunately, it has become common for auto-makers to equip their products with ball-joints and tie-rod ends that are 'lubricated for life,' which is automotive double-speak meaning the things will only last about sixty thousand miles before they must be replaced due to lack of lubrication. They'll last longer if you stick to smooth, paved roads but the bottom line is that you can't lubricate them, meaning they'll wear-out faster than a fitting you CAN lubricate.

The solution to this 'Lifetime Lubrication' bullshit is pretty simple. Some VW ball-joints have a threaded hole for a Zerk fitting. Simply replace the nylon plug with a Zerk and pump away -- your ball-joints will love you for it. Another, less effective method, is to inject grease directly into the fitting through the rubber boot, using a large hypodermic needle. I know it sounds crazy but it works. Indeed, it sounded so crazy that the kid mentioned above had never heard of it nor had any of his friends. Thanks to Conventional Wisdom the kid was convinced the suggestion -- and all of my articles -- had no value, that I was just another geezer blowing smoke up his ass. And besides, his dad told him it was illegal to own a hypodermic needle(!!!).

Ah well.

Wanna nice big hyperdermic needle? Go down to your FLAPS and buy one. It will be hanging on the wall in a blister pack, somewhere near the grease-gun stuff. Plews (brand name) makes one -- their catalog number is 05-037. Cost about three bucks. Cheep! (This is also how you get those extra miles out of your CV joints.)

The 18 gauge hypodermic needle, which at least in California is perfectly leagal to own, is swaged to... you guessed it -- a Zerk fitting! Plug it into the nozzle of your grease gun, stab the needle through the boot of your tie-rod end, CV or ball-joint, and pump away. Yeah, it makes a hole, and yeah, some of the grease will leak out. But the thing will last a lot longer, too.

--Bob Hoover

(*) So how did Muir screw-up on his lube-job instructions? First, he sez to pump until you see the grease come out -- "...indicating that it is full." All that does is top-up the old grease. You want to CHANGE the grease, not just top it off. Keep pumping until you see NEW grease coming out.

Secondly, he sez that if you have a bad Zerk, run down to a service station and have the kid use the pneumatically-powered grease-gun to force grease through the fitting.

Bad, bad idea. What if the fitting is filled with dirt? What if the spring has failed and the ball is rusted in place? (Hint: You'll pump parts of the spring into the joint you're trying to lubricate.) And finally, what if even the powered grease-gun can't force grease through the nipple?

If you have a bad Zerk fitting, replace it. You can buy Zerk fittings at any auto-parts place that sells grease -- they come with the territory. You should keep a couple spare Zerks of each type (they come in both straight and angled flavors) in your tool kit, just as you keep a few spare fuses and a few spare tire-valve cores. It's not anything special, it's what mechanics DO.

In all fairness, the Muir manual mentions replacing Zerk fittings... but only when they fail to make an adequate seal with the nozzle of the grease-gun.

There's a bit more to it than that. -- rsh

No comments:

Post a Comment